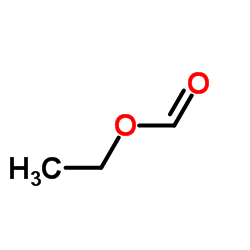

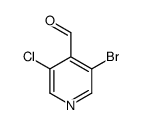

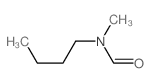

Ethyl formate

Ethyl formate structure

|

Common Name | Ethyl formate | ||

|---|---|---|---|---|

| CAS Number | 109-94-4 | Molecular Weight | 74.078 | |

| Density | 0.9±0.1 g/cm3 | Boiling Point | 54.7±3.0 °C at 760 mmHg | |

| Molecular Formula | C3H6O2 | Melting Point | −80 °C(lit.) | |

| MSDS | Chinese USA | Flash Point | -19.4±0.0 °C | |

| Symbol |

GHS02, GHS07 |

Signal Word | Danger | |

| Name | ethyl formate |

|---|---|

| Synonym | More Synonyms |

| Density | 0.9±0.1 g/cm3 |

|---|---|

| Boiling Point | 54.7±3.0 °C at 760 mmHg |

| Melting Point | −80 °C(lit.) |

| Molecular Formula | C3H6O2 |

| Molecular Weight | 74.078 |

| Flash Point | -19.4±0.0 °C |

| Exact Mass | 74.036781 |

| PSA | 26.30000 |

| LogP | 0.30 |

| Vapour density | 2.5 (vs air) |

| Vapour Pressure | 242.4±0.1 mmHg at 25°C |

| Index of Refraction | 1.356 |

| Stability | Stable. Extremely flammable. May form explosive mixtures with air. Note low flash point and wide explosive limits. Incompatible with strong oxidizing agents, strong bases, strong acids, nitrates. |

| Water Solubility | 11 g/100 mL (18 ºC) |

CHEMICAL IDENTIFICATION

HEALTH HAZARD DATAACUTE TOXICITY DATA

|

| Symbol |

GHS02, GHS07 |

|---|---|

| Signal Word | Danger |

| Hazard Statements | H225-H302 + H332-H319-H335 |

| Precautionary Statements | P210-P261-P305 + P351 + P338 |

| Personal Protective Equipment | Eyeshields;Faceshields;full-face respirator (US);Gloves;multi-purpose combination respirator cartridge (US) |

| Hazard Codes | F:Flammable |

| Risk Phrases | R11;R20/22;R36/37 |

| Safety Phrases | S9-S16-S24-S26-S33 |

| RIDADR | UN 1190 3/PG 2 |

| WGK Germany | 1 |

| RTECS | LQ8400000 |

| Packaging Group | II |

| Hazard Class | 3 |

| HS Code | 2915130000 |

| Precursor 10 | |

|---|---|

| DownStream 10 | |

| HS Code | 2915120000 |

|---|---|

| Summary | 2915120000 salts of formic acid。Supervision conditions:None。VAT:17.0%。Tax rebate rate:9.0%。MFN tariff:5.5%。General tariff:30.0% |

|

Antioxidants in heat-processed koji and the production mechanisms.

Food Chem. 187 , 364-9, (2015) We previously developed antioxidative heat-processed (HP)-koji via two-step heating (55 °C/2days → 75 °C/3 days) of white-koji. In this study, we isolated antioxidants in HP-koji and investigated thei... |

|

|

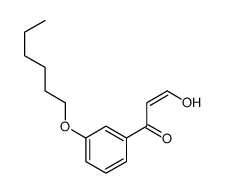

Concurrent production of biodiesel and chemicals through wet in situ transesterification of microalgae.

Bioresour. Technol. 193 , 386-92, (2015) This work addresses an unprecedented way of co-producing biodiesel (FAEE) and valuable chemicals of ethyl levulinate (EL), ethyl formate (EF) and diethyl ether (DEE) from wet in situ transesterificati... |

|

|

Evaluation of injection methods for fast, high peak capacity separations with low thermal mass gas chromatography.

J. Chromatogr. A. 1392 , 82-90, (2015) Low thermal mass gas chromatography (LTM-GC) was evaluated for rapid, high peak capacity separations with three injection methods: liquid, headspace solid phase micro-extraction (HS-SPME), and direct ... |

| Formic Acid Ethyl Ester |

| Ethyl formic ester |

| ETHYL FORMATE/FORMIC ACID ETHYL ESTER |

| Aethylformiat |

| ETHYL FORMATE BAKER ANALYZED REAGENT-500 ML |

| Ethylformiaat |

| Ethyl Formate, Reagent |

| Areginal |

| Ethylformate |

| Ethyl formate, , pure |

| Ethyl Formate |

| MFCD00003294 |

| ethyl formiate |

| ethyl ortho-formate |

| ETHYL FORMATE FOR PHARMA SYNTHESIS |

| EINECS 203-721-0 |

| Ethyl methanoate |

| Formic ether |

| Ethyl formate,AcroSeal,Extra Dry |

CAS#:64-17-5

CAS#:64-17-5 CAS#:124-38-9

CAS#:124-38-9 CAS#:201230-82-2

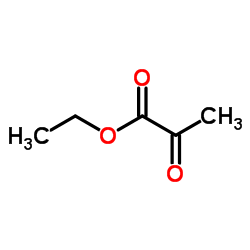

CAS#:201230-82-2 CAS#:617-35-6

CAS#:617-35-6 CAS#:122-51-0

CAS#:122-51-0 CAS#:539-88-8

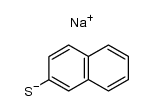

CAS#:539-88-8 CAS#:39689-37-7

CAS#:39689-37-7 CAS#:104-01-8

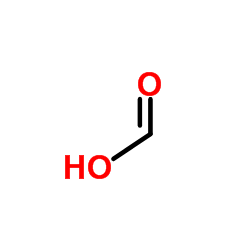

CAS#:104-01-8 CAS#:64-18-6

CAS#:64-18-6 CAS#:454-31-9

CAS#:454-31-9 CAS#:1064678-66-5

CAS#:1064678-66-5![Ethyl 4,7-dihydro-7-oxopyrazolo[1,5-a]pyrimidine-3-carboxylate structure](https://image.chemsrc.com/caspic/232/104556-86-7.png) CAS#:104556-86-7

CAS#:104556-86-7 CAS#:112044-12-9

CAS#:112044-12-9 CAS#:10472-09-0

CAS#:10472-09-0 CAS#:111651-85-5

CAS#:111651-85-5 CAS#:1117-72-2

CAS#:1117-72-2 CAS#:1113049-90-3

CAS#:1113049-90-3 CAS#:111129-64-7

CAS#:111129-64-7![N-[2-(3-methoxyphenyl)ethyl]formamide structure](https://image.chemsrc.com/caspic/405/110339-54-3.png) CAS#:110339-54-3

CAS#:110339-54-3 CAS#:112129-25-6

CAS#:112129-25-6