1313-82-2

| 中文名 | 硫化钠 |

|---|---|

| 英文名 | sodium sulfide (anhydrous) |

| 中文别名 |

硫化碱

无水硫化钠 |

| 英文别名 |

EINECS 215-211-5

Disodium sulfide MFCD00003498 Sodium sulfide |

| 密度 | 1.86 g/mL at 25 °C(lit.) |

|---|---|

| 沸点 | 174ºC |

| 熔点 | 950 °C(lit.) |

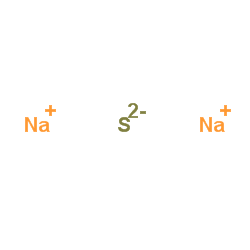

| 分子式 | Na2S |

| 分子量 | 78.045 |

| 精确质量 | 77.951607 |

| PSA | 25.30000 |

| 外观性状 | 多变色的晶体,带有一种令人厌恶的气味 |

| 储存条件 | 储存注意事项 储存于阴凉、通风的库房。远离火种、热源。包装密封。应与氧化剂、酸类分开存放,切忌混储。不宜长久,以免变质。配备相应品种和数量的消防器材。储区应备有合适的材料收容泄漏物。 |

| 稳定性 | 1.遇酸反应,产生硫化氢。水溶液呈强碱性,故又称硫化碱。溶于硫黄生成多硫化钠。工业品因含杂质常为粉红、棕红色、土黄色块。有腐蚀性,有毒。在空气中易氧化生成硫代硫酸钠。吸湿性很强,在100g水中的溶解度为15.4g(10℃),57.3g(90℃)。微溶于乙醇,不溶于乙醚。 2.稳定性 稳定 3.禁配物 酸类、强氧化剂 4.避免接触的条件 空气 5.聚合危害 不聚合 |

| 水溶解性 | 186 g/L (20 ºC) |

| 分子结构 | 1、摩尔折射率:无可用的 2、摩尔体积(cm3/mol):无可用的 3、等张比容(90.2K):无可用的 4、表面张力(dyne/cm):无可用的 5、介电常数:无可用的 6、极化率(10-24cm3):无可用的 7、单一同位素质量:77.95161 Da 8、标称质量:78 Da 9、平均质量:78.0445 Da |

| 计算化学 | 1、疏水参数计算参考值(XlogP):无 2、氢键供体数量:1 3、氢键受体数量:1 4、可旋转化学键数量:0 5、互变异构体数量:无 6、拓扑分子极性表面积(TPSA):1 7、重原子数量:3 8、表面电荷:1 9、复杂度:2.8 10、同位素原子数量:0 11、确定原子立构中心数量:0 12、不确定原子立构中心数量:0 13、确定化学键立构中心数量:0 14、不确定化学键立构中心数量:0 15、共价键单元数量:3 |

| 更多 | 1.性状:无色或米黄色颗粒结晶,工业品为红褐色或砖红色块状。 2.pH值:>7(1%溶液) 3.熔点(℃):1180 4.相对密度(水=1):1.86 5.辛醇/水分配系数:-4.23 6.溶解性:易溶于水,不溶于乙醚,微溶于乙醇。 |

Synonym:Sodium monosulfide; sodium sulfide anhydrous; sodium sulfide with < 30% water of crystallization; sodium sulphid Section 2 - COMPOSITION, INFORMATION ON INGREDIENTS

Risk Phrases: 31 34 50 Section 3 - HAZARDS IDENTIFICATION EMERGENCY OVERVIEW

Contact with acids liberates toxic gas. Causes burns. Very toxic to aquatic organisms.Corrosive.Hygroscopic (absorbs moisture from the air). Potential Health Effects Eye: Causes eye burns. May cause irreversible eye injury. May cause blindness. May cause chemical conjunctivitis and corneal damage. Skin: Causes skin burns. May be absorbed through the skin in harmful amounts. Prolonged and/or repeated contact may cause irritation and/or dermatitis. Contact with skin causes irritation and possible burns, especially if the skin is wet or moist. May cause skin rash (in milder cases), and cold and clammy skin with cyanosis or pale color. Ingestion: Harmful if swallowed. May cause severe and permanent damage to the digestive tract. Causes gastrointestinal tract burns. May cause perforation of the digestive tract. May cause cardiac disturbances. May cause systemic effects. Inhalation: May cause severe irritation of the respiratory tract with sore throat, coughing, shortness of breath and delayed lung edema. Causes chemical burns to the respiratory tract. May cause effects similar to those described for ingestion. Aspiration may lead to pulmonary edema. May cause systemic effects. Chronic: Effects may be delayed. Section 4 - FIRST AID MEASURES Eyes: Immediately flush eyes with plenty of water for at least 15 minutes, occasionally lifting the upper and lower eyelids. Get medical aid immediately. Do NOT allow victim to rub eyes or keep eyes closed. Extensive irrigation with water is required (at least 30 minutes). Skin: Get medical aid immediately. Immediately flush skin with plenty of water for at least 15 minutes while removing contaminated clothing and shoes. Wash clothing before reuse. Destroy contaminated shoes. Ingestion: Do not induce vomiting. If victim is conscious and alert, give 2-4 cupfuls of milk or water. Never give anything by mouth to an unconscious person. Get medical aid immediately. Inhalation: Get medical aid immediately. Remove from exposure and move to fresh air immediately. If breathing is difficult, give oxygen. Do NOT use mouth-to-mouth resuscitation. If breathing has ceased apply artificial respiration using oxygen and a suitable mechanical device such as a bag and a mask. Notes to Physician: Section 5 - FIRE FIGHTING MEASURES General Information: As in any fire, wear a self-contained breathing apparatus in pressure-demand, MSHA/NIOSH (approved or equivalent), and full protective gear. During a fire, irritating and highly toxic gases may be generated by thermal decomposition or combustion. Wear appropriate protective clothing to prevent contact with skin and eyes. Wear a self-contained breathing apparatus (SCBA) to prevent contact with thermal decomposition products. Extinguishing Media: For small fires, use dry chemical, carbon dioxide, water spray or alcohol-resistant foam. Section 6 - ACCIDENTAL RELEASE MEASURES General Information: Use proper personal protective equipment as indicated in Section 8. Spills/Leaks: Vacuum or sweep up material and place into a suitable disposal container. Clean up spills immediately, observing precautions in the Protective Equipment section. Avoid generating dusty conditions. Provide ventilation. Section 7 - HANDLING and STORAGE Handling: Wash thoroughly after handling. Wash hands before eating. Use only in a well-ventilated area. Do not get in eyes, on skin, or on clothing. Keep container tightly closed. Keep away from heat, sparks and flame. Do not ingest or inhale. Discard contaminated shoes. Storage: Store in a cool, dry place. Keep container closed when not in use. Store in a tightly closed container. Keep from contact with oxidizing materials. Keep away from strong acids. Store protected from moisture. Section 8 - EXPOSURE CONTROLS, PERSONAL PROTECTION Engineering Controls: Facilities storing or utilizing this material should be equipped with an eyewash facility and a safety shower. Use adequate general or local exhaust ventilation to keep airborne concentrations below the permissible exposure limits. Exposure Limits CAS# 1313-82-2: Personal Protective Equipment Eyes: Wear appropriate protective eyeglasses or chemical safety goggles as described by OSHA's eye and face protection regulations in 29 CFR 1910.133 or European Standard EN166. Skin: Wear appropriate protective gloves to prevent skin exposure. Clothing: Wear appropriate protective clothing to minimize contact with skin. Respirators: A respiratory protection program that meets OSHA's 29 CFR 1910.134 and ANSI Z88.2 requirements or European Standard EN 149 must be followed whenever workplace conditions warrant respirator use. Follow the OSHA respirator regulations found in 29 CFR 1910.134 or European Standard EN 149. Use a NIOSH/MSHA or European Standard EN 149 approved respirator if exposure limits are exceeded or if irritation or other symptoms are experienced. Section 9 - PHYSICAL AND CHEMICAL PROPERTIES Physical State: Solid Color: white to yellow Odor: rotten egg-like - weak odor pH: Alkaline in solution Vapor Pressure: Not applicable. Viscosity: Not applicable. Boiling Point: 346 deg F Freezing/Melting Point: 197 deg F Autoignition Temperature: Not applicable. Flash Point: Not applicable. Explosion Limits, lower: Not available. Explosion Limits, upper: Not available. Decomposition Temperature: Not available. Solubility in water: 15% @ 20C Specific Gravity/Density: 1.858 Molecular Formula: Mixture Molecular Weight: 0 Section 10 - STABILITY AND REACTIVITY Chemical Stability: Stable at room temperature in closed containers under normal storage and handling conditions. Conditions to Avoid: Incompatible materials, light, exposure to air, exposure to moist air or water. Incompatibilities with Other Materials: Metals, oxidizing agents, acids, carbon, moisture, diazonium salts. Hazardous Decomposition Products: Oxides of sulfur, hydrogen sulfide. Hazardous Polymerization: Has not been reported. Section 11 - TOXICOLOGICAL INFORMATION RTECS#: CAS# 1313-82-2: WE1905000 LD50/LC50: CAS# 1313-82-2: Oral, mouse: LD50 = 205 mg/kg; Oral, rat: LD50 = 208 mg/kg. Carcinogenicity: Sodium sulfide - Not listed by ACGIH, IARC, or NTP. Other: See actual entry in RTECS for complete information. Section 12 - ECOLOGICAL INFORMATION Ecotoxicity: Bacteria: Phytobacterium phosphoreum: EC50 = 4.29 mg/L; 15 minutes; Microtox test Section 13 - DISPOSAL CONSIDERATIONS Dispose of in a manner consistent with federal, state, and local regulations. Section 14 - TRANSPORT INFORMATION IATA Shipping Name: SODIUM SULPHIDE, ANHYDROUS Hazard Class: 4.2 UN Number: 1385 Packing Group: II IMO Shipping Name: SODIUM SULPHIDE, ANHYDROUS Hazard Class: 4.2 UN Number: 1385 Packing Group: II RID/ADR Shipping Name: SODIUM SULPHIDE, ANHYDROUS Hazard Class: 4.2 UN Number: 1385 Packing group: II Section 15 - REGULATORY INFORMATION European/International Regulations European Labeling in Accordance with EC Directives Hazard Symbols: C N Risk Phrases: R 31 Contact with acids liberates toxic gas. R 34 Causes burns. R 50 Very toxic to aquatic organisms. Safety Phrases: S 26 In case of contact with eyes, rinse immediately with plenty of water and seek medical advice. S 45 In case of accident or if you feel unwell, seek medical advice immediately (show the label where possible). S 61 Avoid release to the environment. Refer to special instructions/safety data sheets. WGK (Water Danger/Protection) CAS# 1313-82-2: 2 Canada CAS# 1313-82-2 is listed on Canada's DSL List. CAS# 1313-82-2 is not listed on Canada's Ingredient Disclosure List. US FEDERAL TSCA CAS# 1313-82-2 is listed on the TSCA inventory. SECTION 16 - ADDITIONAL INFORMATION N/A |

|

毒理学数据: 1、急性毒性: 大鼠口经LD50:208mg/kg; 大鼠引入腹膜LD50:147mg/kg; 小鼠口经LCLo:205mg/kg; 易燃。有腐蚀性。硫化钠对皮肤有强腐蚀性,接触硫化钠溶液的工人手部皮肤发生皱裂,发红。 2.急性毒性 LD50:208mg/kg(大鼠经口);205mg/kg(小鼠经口) 生态学数据: 1.生态毒性 EC50:4.29mg/L(15min)(发光菌,Microtox测试) 2.生物降解性 暂无资料 3.非生物降解性 暂无资料 4.其他有害作用 该物质对环境有危害,对水生生物、哺乳动物应给予特别注意。 CHEMICAL IDENTIFICATION

HEALTH HAZARD DATAACUTE TOXICITY DATA

|

| 符号 |

GHS02, GHS05, GHS06, GHS09 |

|---|---|

| 信号词 | Danger |

| 危害声明 | H251-H290-H301 + H311-H314-H400 |

| 补充危害声明 | Contact with acids liberates toxic gas., Corrosive to the respiratory tract. |

| 警示性声明 | P273-P280-P301 + P310 + P330-P303 + P361 + P353-P304 + P340 + P310-P305 + P351 + P338 |

| 个人防护装备 | Eyeshields;Faceshields;full-face particle respirator type N100 (US);Gloves;respirator cartridge type N100 (US);type P1 (EN143) respirator filter;type P3 (EN 143) respirator cartridges |

| 危害码 (欧洲) | C:Corrosive |

| 风险声明 (欧洲) | R31;R34;R50 |

| 安全声明 (欧洲) | S26-S45-S61 |

| 危险品运输编码 | UN 1849 8/PG 2 |

| WGK德国 | 2 |

| RTECS号 | WE1905000 |

| 包装等级 | II |

| 危险类别 | 4.2 |

| 海关编码 | 2830101000 |

| 海关编码 | 2830101000 |

|---|

5.将水合硫化钠置于蒸馏瓶中,在砂浴上加热同时通入氢气。起初硫化钠晶体溶于结晶水中,继续加热,蒸发出的水分被氢气夹带出来,直至逸出的氢气不含水分,水合硫化钠即脱水而转变成硫化钠。

5.将水合硫化钠置于蒸馏瓶中,在砂浴上加热同时通入氢气。起初硫化钠晶体溶于结晶水中,继续加热,蒸发出的水分被氢气夹带出来,直至逸出的氢气不含水分,水合硫化钠即脱水而转变成硫化钠。

图I-11 制备硫化钠的装置 6.制备硫化钠的装置将一个称出重量装着纯净金属钠的安瓿的尖端折断,将安瓿放入侧管1中,立即将1密闭。从2抽真空,并小心加热1使金属钠熔融并经过3流到垂熔玻璃砂板4上。在折断安瓿尖端时所生成的氧化钠就残留在4上。然后将干燥的、纯制氮气猛烈地从2通入,打开1取出安瓿,再称量之,即可得金属钠的净重。将所需量的硫由5加入,用干冰冷却剂将6冷却,把约100mL的纯液氨冷凝在硫上,随后将垂熔玻璃砂板4和管7冷却,直到有液氨聚集在滤板上,于是有一些金属钠溶解在这部分液氨中。使4上面的空间在短时间内压力较大,使钠的氨溶液压向6中与硫的氨液混合。重复操作,每次用小部分氨提取滤板4上的钠,直到钠完全溶解为止。这时生成的为多硫化钠。随着钠溶液的加进,多硫化钠分解而转变成硫化钠。移去6外面的干冰浴,NH3会逐渐蒸发,抽真空,再加热至400~500℃,用力振荡可以打碎结晶,将晶体翻入8中,在氮气氛围中,将8熔封拉下,制得的Na2S很纯,收率几近定量。 7. 工业生产主要有两种方法。

图I-11 制备硫化钠的装置 6.制备硫化钠的装置将一个称出重量装着纯净金属钠的安瓿的尖端折断,将安瓿放入侧管1中,立即将1密闭。从2抽真空,并小心加热1使金属钠熔融并经过3流到垂熔玻璃砂板4上。在折断安瓿尖端时所生成的氧化钠就残留在4上。然后将干燥的、纯制氮气猛烈地从2通入,打开1取出安瓿,再称量之,即可得金属钠的净重。将所需量的硫由5加入,用干冰冷却剂将6冷却,把约100mL的纯液氨冷凝在硫上,随后将垂熔玻璃砂板4和管7冷却,直到有液氨聚集在滤板上,于是有一些金属钠溶解在这部分液氨中。使4上面的空间在短时间内压力较大,使钠的氨溶液压向6中与硫的氨液混合。重复操作,每次用小部分氨提取滤板4上的钠,直到钠完全溶解为止。这时生成的为多硫化钠。随着钠溶液的加进,多硫化钠分解而转变成硫化钠。移去6外面的干冰浴,NH3会逐渐蒸发,抽真空,再加热至400~500℃,用力振荡可以打碎结晶,将晶体翻入8中,在氮气氛围中,将8熔封拉下,制得的Na2S很纯,收率几近定量。 7. 工业生产主要有两种方法。

(2)硫化氢法 将净化后的硫化氢气体通入浓碱溶液中,反应生成硫化碱,控制硫化钠的含量,产物经蒸发浓缩后即为成品。反应如下:

(2)硫化氢法 将净化后的硫化氢气体通入浓碱溶液中,反应生成硫化碱,控制硫化钠的含量,产物经蒸发浓缩后即为成品。反应如下: